DB 6 / 1.2714 Die Tool Steel

Chemical Composition of HOTDIE-H13

| GRADE | Chemical Composition % | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | S | P | Cr | Mo | Ni | V | Cu | ||

| HOTDIE H-13 | 0.32–0.45 | 0.80–1.20 | 0.20–0.50 | 0.03 | 0.03 | 4.75–5.50 | 1.10–1.75 | 0.30 | 0.80–1.20 | 0.25 | |

Properties of DB 6 / DIN 1.2714 Die Tool Steel

The exceptional hot work pre-solidified tool steel has great toughness and high wear resistance. DB-6 die steel condition in strengthened condition in exceptional cases. Normally it’s working hardness is 360 - 430 BHN.

Applications of HOTDIE H-13

Dies for specially drop and close die forgings for

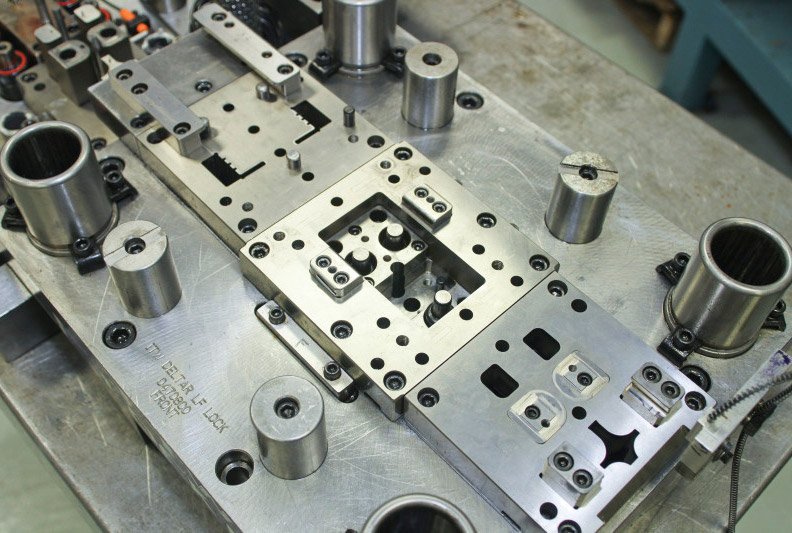

- Hot Forging and Pressing Dies

- Extrusion Dies

- Mandrels and Punches

- Hot Chisels

- Pressure Pads

- Extrusion Stems

- Rams

- Blanking and Bending Tools

- Hot Heading Tools

- Backer Blocks

Related Products

DB 6 / 1.2714 Die Tool Steel